-

-

-

Kathwada GIDC, Ahmedabad - 382430

Welcome to Shark Pump Engineering Pvt. Ltd.

Please fill out the form below and we will get back to you soon.

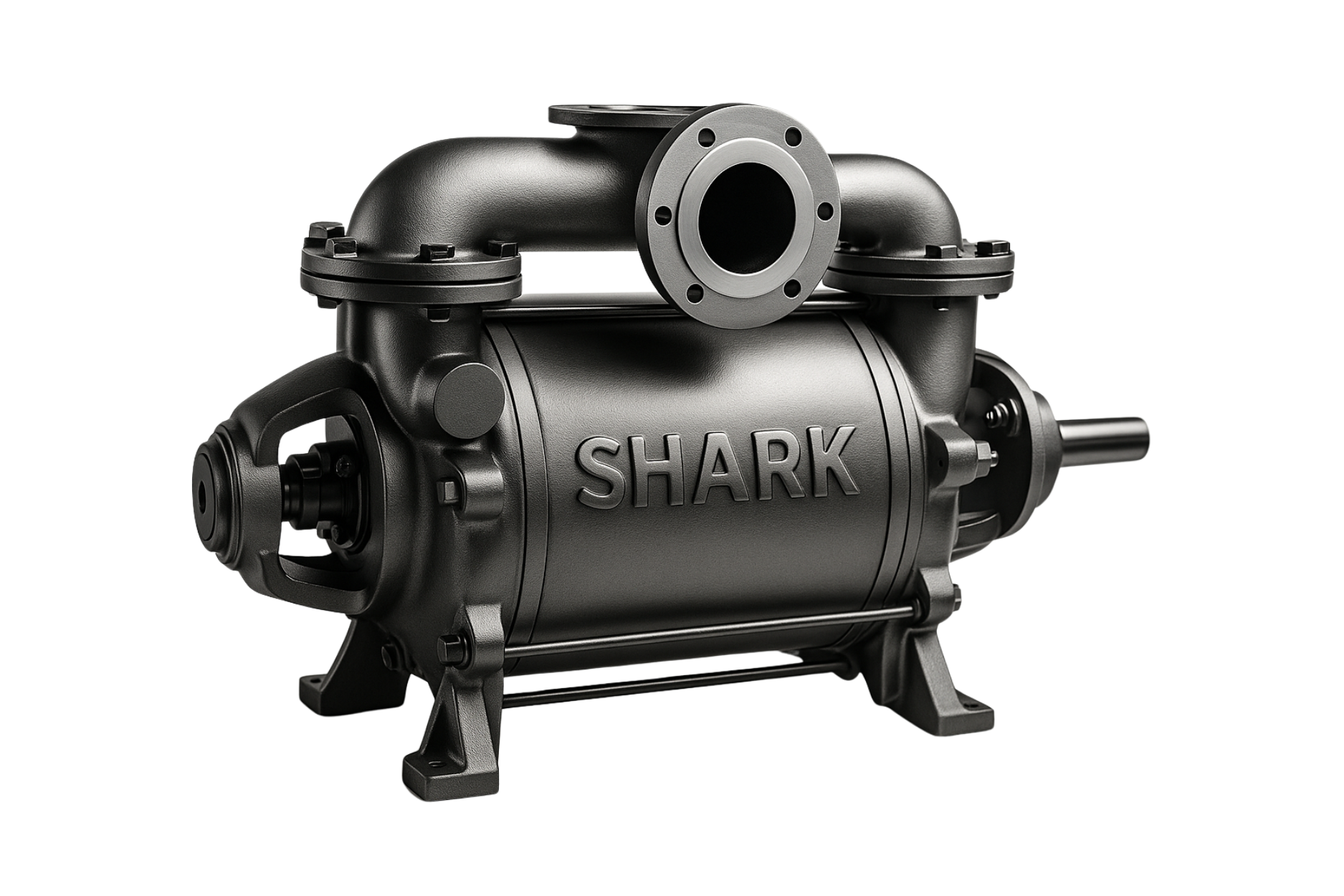

Shark Pump Engineering Pvt. Ltd. is a trusted manufacturer of Liquid Ring Vacuum Pumps built to deliver high efficiency, durability, and reliable performance across various industries. These pumps are engineered to handle liquid–vapor mixtures smoothly and operate continuously even in demanding environments.

Shark’s Liquid Ring Vacuum Pumps are widely used for vacuum filtration, vapor recovery, and moisture extraction in critical industrial systems. Their robust design ensures long life, reliable suction, and efficient handling of gas–liquid mixtures with consistent vacuum output.